Radial Tire and Tubeless Tire: Tire manufacturers have recently unveiled two innovations to ease driving on the roads tubeless and radial tires. Tires play an essential part in maintaining safe roadway conditions; traditionally made using inner tubes filled with air cushioned with foam filler to provide smooth vehicle movement, these innovations now utilize tubeless designs with no inner tube at all and feature radial tread patterns instead.

Tubeless tires offer better air pressure management than their conventional counterparts; in this instance, the air is pumped in through a valved nozzle which maintains ideal conditions to support vehicle weight. A puncture may result in losing air, necessitating tube replacement or repair as soon as a sharp object punctures through it; to coTire manufacturers have recently unveiled two innovations to ease driving on the roads tubeless and radial tires.

Tires play an essential part in maintaining safe roadway conditions; traditionally made using inner tubes filled with air cushioned with foam filler to provide smooth vehicle movement, these innovations now utilize tubeless designs with no inner tube at all and feature radial tread patterns instead.

Tubeless tires offer better air pressure management than their conventional counterparts; in this instance, the air is pumped in through a valved nozzle which maintains ideal conditions to support vehicle weight.

A puncture may result in losing air, necessitating tube replacement or repair as soon as a sharp object punctures through it; to combat this problem tire manufacturers came up with tubeless designs made up of steel-reinforced butyl rubber versions – but more on that later! Here we discuss both types of tires.

Checking air pressure regularly will reduce punctures to tubes since sharp objects cannot enter tire and tube treads through incorrect air pressure settings. Unfortunately, many individuals disregard this advice, failing to check air pressure regularly resulting in punctures.

What is a Radial Tire?

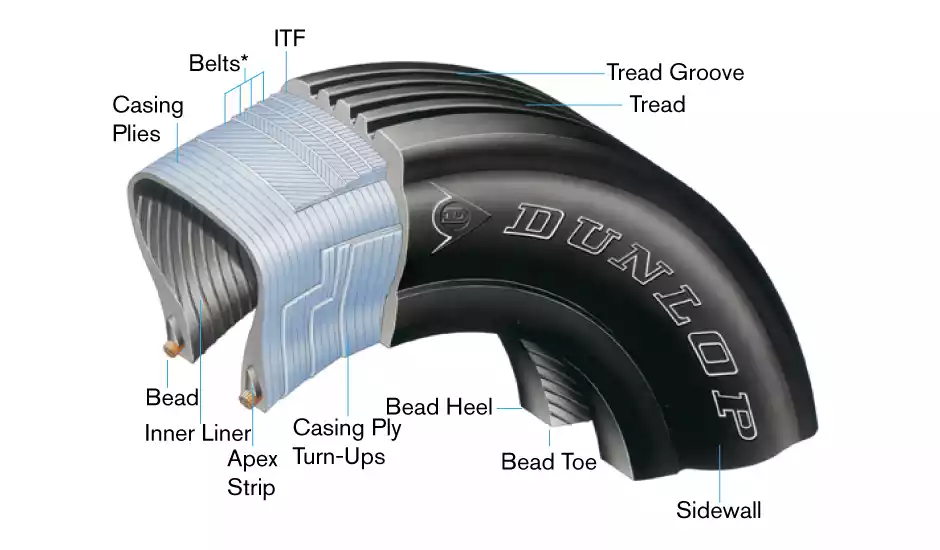

Radial tires feature inner plies arranged in an alternating radial pattern, starting in the center and moving outward. Made of polyester or steel cord, plies run parallel with travel direction while layers are secured by belts or overlapped to add strength and stability to each tire.

Radial tires are composed of rubber-coated belts that reinforce both their treads and sidewalls for greater rigidity and durability and to allow their sidewalls to flex independently from one another for improved traction, fuel economy, and fuel economy.

Radial tires can be found on many vehicles including automobiles, trucks, commercial vehicles, and motorcycles. Nowadays they’re the preferred choice due to their excellent performance characteristics as well as numerous advantages over bias-ply models.

What is the definition of tubeless tires?

Tubeless tires do not rely on inner tubes to maintain air pressure; rather they use tires specifically designed to seal airtight without an inner tube.

Tubeless tires utilize inner liners made of rubber compounds as seals to stop air escaping through cracks in their casing and out through tire beads that form tight seals with wheel rims preventing air loss from the tire itself. This combination prevents air loss while protecting its contents.

Tubeless tires offer many advantages to drivers. First and foremost is reduced sudden deflation caused by punctures or tube failures; tubeless tires deflate more gradually so the driver has time to safely stop his or her vehicle before deflating completely. Also, punctures are easier to repair with sealants applied directly onto the inner lining or patches applied over damaged areas of a tubeless tire; finally, they may provide smoother ride quality as they absorb road imperfections better than traditional rubber treads do.

Tubeless tires have become an increasingly popular option on cars, bikes, and motorcycles alike as well as heavy-duty vehicles. Their many benefits include superior safety features like reduced rolling resistance and convenience features compared to inner-tubed versions.

Importance of understanding the differences between the two?

Understanding the difference between tubeless and radial tires for various reasons is absolutely vital.

- Understanding the differences between tubeless and radial tires will enable people to make an informed choice when purchasing new ones for their vehicles. Learning their respective advantages and disadvantages will enable individuals to pick those most suited to their individual needs, budget, and driving conditions.

- Radial and Tubeless Tires differ significantly when it comes to performance and safety features, giving drivers a means of selecting one with ideal traction, stability, and handling characteristics for their driving style, environment, and needs. Gaining insight into safety aspects like puncture resistance handling or sudden deflation is also vital when making informed choices.

- Knowing the differences between tubeless and radial tires when it comes to repairs and maintenance is of great significance, given their distinct construction methods. Tubeless tires require different techniques of repair than their radial counterparts due to being constructed differently than their predecessors; understanding this difference will enable optimal performance, extended tire lifespan, and reduced risks from accidents or tire failure.

- Tubeless and radial tires often vary significantly in price, and it is essential that individuals understand all of the variables contributing to these variations in cost – including initial purchase cost, repair expenses, fuel economy concerns, and lifespan considerations. By understanding costs individuals can make more informed decisions without jeopardizing safety or performance.

- Technology Advancements. As technology evolves in the tire industry, new innovations emerge regularly. Knowing the difference between tubeless and radial tires will keep you abreast of developments within the tire world, helping adapt more readily to emerging trends when replacing or upgrading tires.

Understanding the differences between tubeless and radial tire types will enable individuals to make more informed decisions regarding tire selection, maintenance costs, safety considerations, and driving safety. Doing so promotes safer driving practices while increasing tire life span and performance as well as staying abreast of new advancements in tire technology.

Radial Tires

Radial tires were first introduced and quickly revolutionized tire manufacturing, yet many may remain unaware of what makes these revolutionary treads tick.

Here are a few facts about them that should make you consider switching over:

Radial Tires feature layers of belts and cords extending radially out from their center, such as polyester or steel cords set at 90-degree angles to the direction in which they travel. Belts reinforce these cord layers for additional support.

Advantages:

- Improved Traction and Grip: With their radial construction, tires with improved traction and grip enable increased contact between tire treads and road surface for greater traction and grip, leading to better cornering or braking maneuvers and enhanced handling performance.

- Radial Tires Provide Superior Fuel Economy: Radials’ flexible sidewalls significantly decrease rolling resistance and enhance fuel economy over other tire types.

- Stability and Control at High Speeds: Radial tires offer outstanding control at any speed, while their construction helps minimize heat accumulation to increase stability when heavy loads are applied to them.

Disadvantages of Radial Tires:

- Because radial tires require more complex production techniques to produce than their bias-ply counterparts, their prices tend to be more costly compared to bias-ply tires.

- Radial Tires may be more vulnerable than their rival tire types to road hazards. Although their superior performance often makes radials attractive choices, their flexible sidewalls may not offer as much protection against potholes and sharp objects as their stiffer counterparts do.

- Radial tires can be more challenging to repair due to all their layers of belts and cords; making repair more laborious.

- Radial tires have become popular choices due to their superior performance. Used on passenger cars, motorbikes, trucks, and more types of vehicles alike – their benefits such as fuel economy improvements and enhanced traction have resulted in widespread adoption of this style of tire.

Tubeless Tires

Tubeless tires occupy less space on a truck by eliminating their need for air pressure regulation by not needing inner tubes for inflation purposes.

Below are three facts to keep in mind about tubeless tires:

- Tubeless tire designs incorporate an inner liner that acts as an airtight sealant to stop air from escaping, typically made of rubber-based compounds like this inner, liner that acts like sealants to seal tightly against air leakage and prevent air loss from the tire to its environment. Tire beads also work to seal tightly against their respective rims for additional air tightness.

- Without inner tubes, there is less risk of sudden inflation due to punctures or failures; further increasing safety by permitting gradual deflation of air pressure allowing drivers to stop their vehicles safely. Fixing punctures on tubeless tires is often easier. Sealants or patches may be applied directly onto the inner lining to restore original functionality and save both time and effort in fixing punctures quickly and efficiently.

- Tubeless tires tend to provide a smoother driving experience compared to their counterparts with inner tubes since their lack of an inner tube means better road irregularity absorption, leading to an overall more comfortable and pleasurable driving experience.

Disadvantages of Tubeless Tires:

- The initial cost of tubeless tires tends to be more costly due to additional materials and technology required in their construction, due to increased materials costs.

- Tubeless Tires can become particularly vulnerable to Rim damage when their air pressure suddenly decreases unexpectedly and they come in direct contact with an unprotected rim due to severe tire damage without an inner tube in place.

- Tubeless Tires can be more challenging to mount and remove than their inner tube-equipped counterparts, necessitating specific tools and techniques in order to seal airtight between tire bead, wheel rim, and wheel bead.

- Tubeless tires have quickly become an increasingly popular option on vehicles of all kinds – passenger cars, bikes and motorcycles alike as well as some heavy duty ones. Drivers seeking convenience and reliability often opt for these innovative wheels which offer improved puncture repair while simultaneously increasing comfort levels and offering greater puncture safety.

Comparison between Radial Tire and Tubeless Tire

There are various factors to keep in mind when comparing tubeless and radial tires, and this comparison highlights their main differences.

Performance:

- Whilst Radial tires generally offer better grip and traction due to a larger contact surface with the road surface, tubeless tires often offer superior handling performance as well as brake performance.

- Radial tires offer improved cornering stability due to their constructed sidewalls which give greater flexibility and control, giving greater cornering stability than non-radial counterparts.

- Tubeless tires offer greater ride comfort by better-dampening road imperfections, making for an overall smoother journey.

Safety:

- Tubeless tires offer significant puncture protection over their radial counterparts; sealants or patches can easily seal punctures quickly so as to minimize air loss while driving with reduced air loss during a journey. Radial tires tend to puncture more readily due to being made up of multiple sections and their repair can often prove more challenging than expected.

- Tubeless Tires Provide Superior Handling When Shock Deflation Occurs. In cases of sudden deflation or air loss, tubeless tires tend to offer superior handling due to their gradual deflation process that enables drivers to stop safely while keeping control over their vehicle compared with more rapidly deflating radial tires that may impact control more severely.

Maintenance and Repair:

- For tubeless tires, puncture repair can often be completed without having to take apart their wheels from their rims, while more complex techniques might require professional assistance due to their design.

- Repair Services Are Available, Due to their increasing popularity, tubeless tire repair services now provide more comprehensive support. This makes it simpler for customers to access assistance or replacement parts when necessary.

Cost and Longevity:

- Due to their construction and performance characteristics, radial tires tend to be more costly than tubeless alternatives. Both radial tires and tubeless can provide good durability and longevity when maintained appropriately, though their exact lifespan depends on factors like driving habits, road conditions,s and maintenance schedules.

- Before choosing between tubeless or radial tires, take into consideration your individual driving needs and conditions. Each option offers advantages and disadvantages; selecting the ideal tire can have an exponentially positive effect on performance, safety, and driving enjoyment.

Conclusion

Both tubeless and radial tires possess their own advantages, and the decision between them ultimately rests on your particular driving requirements and personal preferences. Radial tires are more comfortable as well as have longevity and energy efficiency, making them the ideal choice for commuting in every day. However tubeless tires emphasize safety by offering better puncture resistance and sealing capabilities and make them a great option for long-distance travel as well as off-roading activities.