The Cloud Point and Pour Point of any liquid fuel are two crucial physical properties. As their names imply, the cloud point measures the temperature where crystallization first begins in a test sample under specific test conditions; it serves as an accurate gauge of its performance in cold climate conditions. Conversely, the pour point is the opposite; this temperature represents where oil moves freely enough that pumps can easily access it for use – this difference may seem subtle but has huge ramifications on how we use fuels.

What Is Cloud Point?

Cloud Point in the industry refers to the temperature at which fuels begin to form a cloudy appearance, often appearing cloud-like in appearance. At this temperature, wax crystallization begins, leading to thickened fuel that can clog filters and injectors as it solidifies in thick layers on engine components. Furthermore, wax can also form an emulsion when combined with water in pipelines – an especially critical property during cold weather months – this parameter is commonly known as Wax Appearance Temperature or WAT for crude and heavy oil respectively.

Olive oil begins to solidify at temperatures as low as 4 degrees Celsius in temperate regions; winter temperatures often fall below this threshold, making the olive oil solidify into waxy-white sediment at the bottom of its container. Two methods exist for measuring cloud points- manual and automated methods.

What Is Pour Point?

A fuel’s pour point, on the other hand, is defined as the lowest temperature at which its flow will still continue unimpeded; also known as its “performance threshold”. Once above this point, however, its flow stops altogether and begins freezing over.

An increase in paraffin concentration often correlates to a higher pour point in crude oil, particularly those produced from plant material. Two methods can be used to measure temperature; cloud point measurement or paraffin content measurement.

Know About Cloud Point

The cloud point is the temperature at which liquid fuel, lubricants, or other fluids begin to form visible clouds or solidify when cooled – an essential metric when evaluating fuel quality, stability, and cold weather performance.

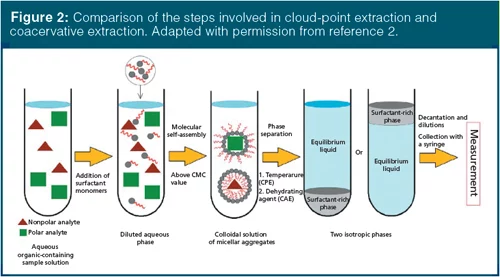

Measurement methods:

- To calculate a cloud point, one needs to observe where cloudiness or haze first forms in a liquid sample at room temperature. A number of measurement techniques exist such as visual observation, optical sensor readings, and automated instrumentation systems.

Factors Affecting Cloud Point:

- A substance’s cloud point temperature can be altered by multiple factors, including contaminants or impurities such as paraffin or waxes that increase its cloud point characteristics. Furthermore, molecular structures of liquid can have an impact on how its cloud point behaves.

Significance and applications:

- Fuel Stability and Quality: The cloud point serves as an indicator of fuel stability and quality. It helps detect any contaminants or impurities present that could impact engine performance, combustion efficiency, or fuel performance – particularly during cold weather operations. Fuels with lower cloud points offer superior cold-weather performance.

- Lubricant Performance: Cloud Point is used in the lubricant sector to measure the performance and quality of lubricants. High Cloud Point values may indicate oil thickening and reduced lubricity at lower temperatures.

- Cold Weather Operations: Cloud point is especially crucial for industries and regions experiencing cold temperatures, to ensure fuels, lubricants, and other fluids can still function and flow optimally even at lower temperatures.

Comparative Analysis with Pour Point:

Cloud Point and Pour Point are related yet distinct parameters, where Cloud Point refers to the temperature where cloudiness forms and Pour Point refers to the lowest temperature at which a liquid will still flow under certain circumstances. It typically falls lower than cloud Point due to showing that substances can remain liquid and continue flowing even as temperatures decline.

The cloud point is essential to selecting appropriate fuels and oils, optimizing processes, and assuring reliability – especially when working in cold climates.

Know About Pour Point

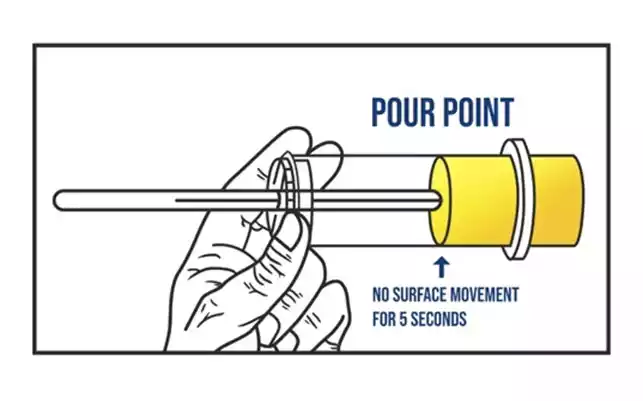

The pour point refers to the lowest temperature at which a liquid, typically a fuel or a lubricant, ceases to flow under specific testing conditions. It is a critical parameter used to assess the low-temperature performance and flow characteristics of substances, particularly in cold weather conditions.

Measurement Methods:

- The pour point of a liquid is determined by gradually cooling a sample and observing the temperature at which it no longer flows. This is typically assessed using standardized testing methods, such as ASTM D97 or ISO 3016, which involve tilting the sample vessel and monitoring flow behavior.

Factors Influencing Pour Point:

- Several factors can affect the pour point of a substance. The presence of waxes, paraffin, or other solid components can raise the pour point temperature, as these substances tend to solidify and increase viscosity at lower temperatures. Additionally, the molecular structure and composition of the liquid can influence its pour point characteristics.

Significance and Applications:

- Fuel Flow Characteristics: The pour point is crucial for evaluating the flow characteristics of fuels, especially in cold climates. It ensures that fuels can still flow and be effectively pumped, transported, and burned at low temperatures. Fuels with lower pour points are desirable as they have improved cold-weather operability.

- Oil Transportation and Storage: Pour point is essential in the oil industry for determining the handling, transportation, and storage conditions of oils. Oils with high pour points may solidify, become more viscous, and impede flow, making it challenging to transfer or pump them efficiently. By considering the pour point, suitable handling and storage procedures can be established to ensure optimal flow and prevent operational issues.

- Cold Weather Performance: The pour point of lubricants is critical in various industries, such as automotive, aviation, and manufacturing, where machinery and equipment operate in cold environments. Lubricants with lower pour points ensure proper lubrication, reduce friction, and prevent damage or failure of moving parts even at extremely low temperatures.

Comparison with Cloud Point:

- While the cloud point indicates the temperature at which cloudiness or haze appears in a liquid, the pour point represents the temperature at which the liquid stops flowing. The pour point is generally a lower temperature than the cloud point since it defines the practical limit of flowability. While both parameters relate to low-temperature performance, pour point specifically focuses on the ability of a substance to remain in a liquid state and flow under specific conditions.

The pour point of fuels and lubricants is crucial for selecting appropriate products, optimizing transportation and storage processes, and ensuring reliable performance in cold weather conditions.

Cloud Point and Pour Point Importance in Different Industries

Cloud point and pour point are important parameters in many industries, particularly those dealing with fuels, oils, or substances susceptible to temperature variations – industries that rely heavily on cloud point and pour point readings for product production and distribution.

Fuel Industry:

- a. Quality and Stability: Both cloud point and pour point can be used as metrics of fuel quality and stability, with higher cloud points often signaling impurities or contaminants which could compromise engine performance or economy. The pour point is defined as the lowest temperature at which fuel will flow at once; its useability in cold weather conditions depends upon this threshold value.

- b. Cold Weather Operation: For fuel producers, distributors, and users living in regions with lower temperatures, the cloud point and pour point are essential in maintaining the optimal function of their products in cold conditions – helping prevent issues like blockages in fuel lines or engine failure.

Lubricant Industry:

- a.Performance Assessment: Cloud point and Pour point are crucial in evaluating lubricant performance and suitability. High cloud points can result in thickened oil that could compromise machinery or engine performance, while pour points represent temperatures at which lubricants will flow freely, which ensures their effectiveness during cold weather conditions.

- b. Cold Weather Lubrication: When operating equipment in cold climates, it’s essential to use lubricants with lower pour points in order to minimize friction and ensure proper lubrication. This is especially important in industries such as automotive manufacturing and aviation where equipment must be reliable even under the most severe cold conditions.

Transport and Storage of Oil:

- a.Pour Point: The pour point is an essential factor when it comes to oil storage and transport. Oils with higher pour points often solidify quickly, leading to obstructions that make handling and transport more challenging.

- b.Storage Stability: Cloud point is an essential indicator of oil storage stability. Exceeding it could signal that wax crystals or other solid contaminants have formed, leading to reduced flow rates or compromised product qualities that could compromise their storage stability and lead to further complications for product storage facilities.

Petrochemical Industry:

- a. Process Optimization: A key aspect of process optimization in the petrochemical industry is process optimization through Cloud Point and Pour Point measurements, which help refiners and distillers adjust processes and formulations in order to meet desired specifications for improved product performance. By understanding these parameters, producers are better able to adjust processes as necessary and meet desired performance targets more easily.

- b.Product Development: Cloud point and pour point data is vital in developing new petrochemical products. Manufacturers use them to formulate formulations that suit specific application and temperature needs of customers.

Cloud point and pour point measurements play an essential role in various industries to assess fuel performance, lubricant properties, and flow characteristics of products. Manufacturers, distributors, and end users rely on these parameters to ensure products remain functional in various temperature environments.

Cloud Point and Pour Point: Differences

Each parameter used to assess low-temperature liquid behavior, especially fuels and oils has different definitions cloud point and pour point are closely related but also have several key distinctions-

Definition and Measurement Methods:

- Cloud Point: The cloud point refers to the temperature at which liquid begins to produce visible cloudiness or solid particles when it cools, measured by watching when its appearance first becomes hazy; automated or visual instruments may be used for this measurement.

- Pour Point: Pour temperature measures the lowest temperature where liquid will flow under specific testing conditions, and can be measured by tilting a sample vessel to observe when flow has stopped; testing methods like ASTM D97 and ISO 3016 can also be used to gauge pour point.

Flow Behavior:

- Cloud Point: Cloud points do not assess directly the flow characteristics of liquids; rather they serve to identify temperatures where visible cloudiness arises, suggesting the presence of impurities or solid particles in the solution.

- Pour Point: The pour point is closely linked with fluid dynamics; it marks the lowest temperature below which a liquid will still flow under given conditions. As such, its existence serves as a measure of its flowability at lower temperatures.

Significance and Applications:

- Cloud Point: Cloud points play an integral part in assessing fuel stability and performance during cold weather, helping identify any impurities or contaminants which might compromise engine performance or operational feasibility.

- Pour Point: Pour point is essential in evaluating low-temperature flow characteristics and performance, to ensure liquids can move freely through machinery at low temperatures. This ensures a fluid path can be achieved.

Temperature Relationship and Cloud Point in Fluids:

- Cloud Point: The cloud point of a fluid is typically higher than its pour point, which indicates when clouds or haze begin to appear before solidification occurs and liquid ceases to flow completely or ceases flowing completely.

- Pour Point: Generally lower than its cloud point counterpart, the pour point represents the temperature at which liquid no longer flows freely – an important indication of practical limitations to flowability during specific test conditions.

Cloud point and Pour point are two specific parameters that provide insights into the low-temperature behavior of liquids, with Cloud point measuring cloudiness, haze, or fog; Pour point assessing characteristics such as flow characteristics as well as temperatures below which liquids cease flowing – essential factors when assessing liquid performance, stability and usability under cold weather conditions.

Table Difference:

| Cloud Point | Pour Point |

|---|---|

| The temperature where cloudiness appears | The lowest temperature where liquid ceases to flow |

| Observing visible cloudiness | Tilting sample to observe flow behavior |

| Indicates the presence of solid particles | Determines flowability of the liquid |

| Fuel quality, stability, and cold weather | Low-temperature flow characteristics |

| operability assessment | assessment |

| Generally higher than the pour point | Generally lower than Cloud point |

| Indicates potential solidification | The practical limit of flowability |

| before complete solidification | at low temperatures |

Future innovations and developments of Cloud Point and Pour Point

Future advances and developments relating to cloud point measurement could include:

- Advancements in Measurement Techniques: Advancements are expected in measurement techniques, such as the creation of more precise instruments for cloud point and Pour Point determination, that could offer increased accuracy, faster testing times, or enhanced data collection capabilities.

- Nanotechnology and Additive Innovation: Nanotechnology and innovative additives may lead to fuels and oils with improved performance at lower temperatures, thanks to nanostructured materials, tailored additives, or other technologies that modify cloud point and pour point characteristics – thus leading to better flowability and stability under extremely cold conditions.

- Predictive Models and Simulations: Simulations and predictive models can provide invaluable insight into molecular composition and structure to accurately forecast cloud point and pour-point behaviors based on cloud point/pour point models, providing clarity into their influences on various factors to facilitate the formulation of optimal products and more efficient production processes.

- Sustainable Cold: One focus may be to develop eco-friendly alternatives with enhanced properties for cold temperatures, such as biofuels, renewable oils, and greener add-ins with lower pour points and cloud points.

- Standards and Regulations Specific to Industry: As industries that depend on low-temperature operations develop industry-specific regulations and standards, such standards will help ensure reliable measurements as well as quality control and product performance.

- Integration of the Internet of Things and Data Analytics: Combining IoT with data analytics enables real-time monitoring of cloud point and point pour data, providing real-time analytics that enables proactive maintenance, optimization of cold weather operations, and predictive analysis in order to anticipate issues with flowability and performance at extreme temperatures.

- Cross-Industry Collaborations: Working across industries such as fuel, lubricant, and petrochemical can lead to cross-pollination in technology and knowledge sharing that leads to innovative approaches as well as advancements in cloud point measurement and application.

Future cloud and pour points will likely involve more precise measurements and tailored solutions, providing us with greater insight into low-temperature liquid behavior, which ultimately improves product performance and reliability during cold weather conditions.

Conclusion

Cloud point and Pour Point are significant features of temperature in petroleum products, including lubricants and fuels. The cloud point is that temperature where the crystals of paraffin wax begin to form, obscuring the liquid. In contrast, the pour point is the temperature where the liquid stops flowing and turns semi-solid. The cloud point influences its appearance as well as the filtration characteristics of the product and the pour point affects its ability to function in cold conditions. Both are vital in the determination of the performance as well as handling characteristics of oil products. They ensure the best performance in different environments.